Guide to Electric Marine Propulsion Systems.

The global shipping industry is undergoing its biggest technological shift since the transition from sail to steam. With regulators tightening emissions rules and operators under pressure to cut fuel costs, attention is turning toward electric marine propulsion systems.

These systems, once considered niche technology particularly for small vessel types, are now being scaled up—appearing on larger passenger ferries, inland vessels, cruise ships, and even pioneering prototypes for deep-sea transport. But what exactly are they, how do they work, and where do they make the most sense?

Diesel vs. Electric

Electric motors, however, are changing the equation. On their own, electric motors achieve 90–95% efficiency when converting electricity into propulsion. The important part is which energy source is being used to generate the electricity > describe further. Describe table.

At the heart of every ship is its propulsion system—the machinery that turns energy into forward motion. For more than a century, that job has belonged to the diesel engine, most commonly arranged in a direct-drive system. In this setup, the crankshaft of the engine connects directly to the propeller shaft, often without an intervening gearbox. The simplicity of this arrangement makes it highly efficient and cost effective. It can convert around 45–50% of the chemical energy in fuel into shaft power, with only minimal losses (1–3%) in the shaft line. In practice, this means overall efficiencies of 44–48%, which is incredibly high.

Electric motors, by contrast, achieve 90–95% efficiency in converting electricity into propulsion. But the critical question is: where does the electricity come from? If it is generated onboard by a diesel genset, the chain of conversion losses reduces overall efficiency but offers flexibility in energy sources to reduce emissions and pollution. If power is drawn from a battery system, the picture looks very different and almost doubles overall system efficiency to 83-87%!

| Propulsion setup | Conversion steps | Net efficiency | Notes |

|---|---|---|---|

| Diesel direct drive (two-stroke, slow-speed) | Fuel → engine with integrated shaft directly driving propeller (45–50%) | 44–48% | Very efficient for long-haul, steady sailing. Proven, robust system. |

| Diesel genset + electric motor | Fuel → generator (~45%) → power electronics (95–97%) → motor (92–95%) | 40–42% | Slightly less efficient than direct drive; adds flexibility for hybrid designs. |

| Battery + electric motor | Battery discharge (~95%) → power electronics (95–97%) → motor (92–95%) | 83–87% | Much higher than burning diesel, but constrained by energy density and storage limits. |

This comparison shows why context matters. Direct-drive diesels remain the most efficient way to burn fuel for transoceanic voyages, where vessels operate at steady loads for thousands of nautical miles. Diesel-electric systems, though slightly less efficient overall, introduce flexibility by enabling hybrid configurations allowing ships to operate quietly and with lower emissions in ports or environmentally sensitive areas while still relying on conventional fuel offshore. Battery-electric propulsion, however, stands out for sheer efficiency: with net conversion efficiencies above 80%, it delivers nearly twice the usable propulsion energy from each unit of input compared to burning diesel.

Asides from the efficiency advantage. A key benefit of electric drives is that they don’t care where the electricity comes from. Batteries, hydrogen fuel cells, or methanol generators,can all plug into the same system essentially making them future proof in terms of what energy source it uses. That flexibility makes electric propulsion far more adaptable in a world where fuel regulations and technologies are shifting rapidly.

Where the Power Comes From.

Every electric motor needs a power source, and in shipping today there are four main contenders: batteries, fuel cells, and hybrids. Each comes with its own set of strengths and trade-offs, and each is already finding its place in the marine world.

01. Batteries

Batteries, as discussed before, remain the most efficient option when paired with electric drives, offering overall energy-conversion efficiencies above 80%, almost double what is possible with diesel. They also eliminate local emissions, run quietly, and deliver instant torque. However, the challenge lies in energy density. Marine fuels such as heavy fuel oil pack the equivalent of around 12,000 Wh/kg, while today’s lithium-ion marine batteries systems typically provide only 150–200 Wh/kg (even lower when considering all needed system auxiliaries such as converters, coolers, etc). That gap means batteries are far heavier and bulkier, taking up valuable space and limiting their use to shorter routes only. Cost is another hurdle: although battery prices have fallen nearly 90% since 2010, the upfront capital costs for large installations remain high compared to diesel. As a result, fully battery-electric propulsion is best suited to short- and medium-distance operations, where efficiency and zero-emission sailing can be fully realized.

In practice, this is already happening. Some Norwegian ferries now carry more than 5 MWh of batteries, enough to power dozens of crossings before plugging in to recharge. Denmark’s MF Ellen, with a 4.3 MWh pack, runs the world’s longest fully electric ferry route at 22 nautical miles. And in South America, Buquebus made headlines in 2025 with the launch of the China Zorrilla, a 40 MWh all-electric ferry capable of transporting 2,100 passengers and 225 vehicles across the River Plate, demonstrating that even very large vessels can run fully battery electric.

The “China Zorrilla” from Buquebus

02. Hydrogen

Hydrogen fuel cells take a different approach to powering ships. Instead of storing electricity in large batteries, they generate it onboard through an electrochemical reaction between hydrogen and oxygen. The process itself is clean, releasing only water vapor and heat as byproducts.

There is intense interest in hydrogen because, at least in theory, it could be the perfect marine fuel. Hydrogen is the most abundant element in the universe and, if produced using renewable electricity, it offers a pathway to truly zero-emission propulsion. It also has high energy density by weight—about 33,000 Wh/kg, nearly three times higher than marine diesel, which makes it attractive for very large vessels.

But the reality is more complicated. While hydrogen has a very high energy density by weight, its volumetric energy density is low, meaning it requires much larger tanks than diesel to carry the same amount of energy. Even in liquid form at –253 °C, hydrogen stores only about a quarter of the energy per liter compared to marine fuels, creating significant space and design penalties. Safety is another concern: hydrogen is highly flammable, and storing it as either a cryogenic liquid or a compressed gas at 350–700 bar demands heavy tanks, complex insulation, and specialized bunkering infrastructure. Cost also remains prohibitive. Green hydrogen, made from renewable electricity via electrolysis, is currently several times more expensive than marine diesel, while most hydrogen produced today is “grey,” derived from natural gas with a large carbon footprint. Finally, and perhaps most importantly of all, is the issue of efficiency. Producing hydrogen consumes vast amounts of electricity; liquefaction or compression uses even more; and converting it back into electricity in a fuel cell introduces further losses. By the time it reaches the propeller, only about 25–35% of the original renewable electricity is left—far below the 80%+ well-to-propeller efficiency achieved by batteries.

MF Hydra

Despite these challenges, hydrogen fuel cells are no longer just a laboratory technology. Real-world vessels are already operating. In 2023, Norway’s MF Hydra entered service as the world’s first liquid-hydrogen ferry, equipped with a 400 kW fuel-cell system and cryogenic storage tanks. The EU-backed HySeas III project is developing the first sea-going hydrogen ferry in Scotland, while Japan, South Korea, and California are also investing heavily in hydrogen-powered pilot vessels.

More is on the horizon. As costs fall, green hydrogen production scales, and safety systems mature, hydrogen fuel cells are expected to play an important role in short- and medium-range zero-emission shipping.

03. Hybrid Systems

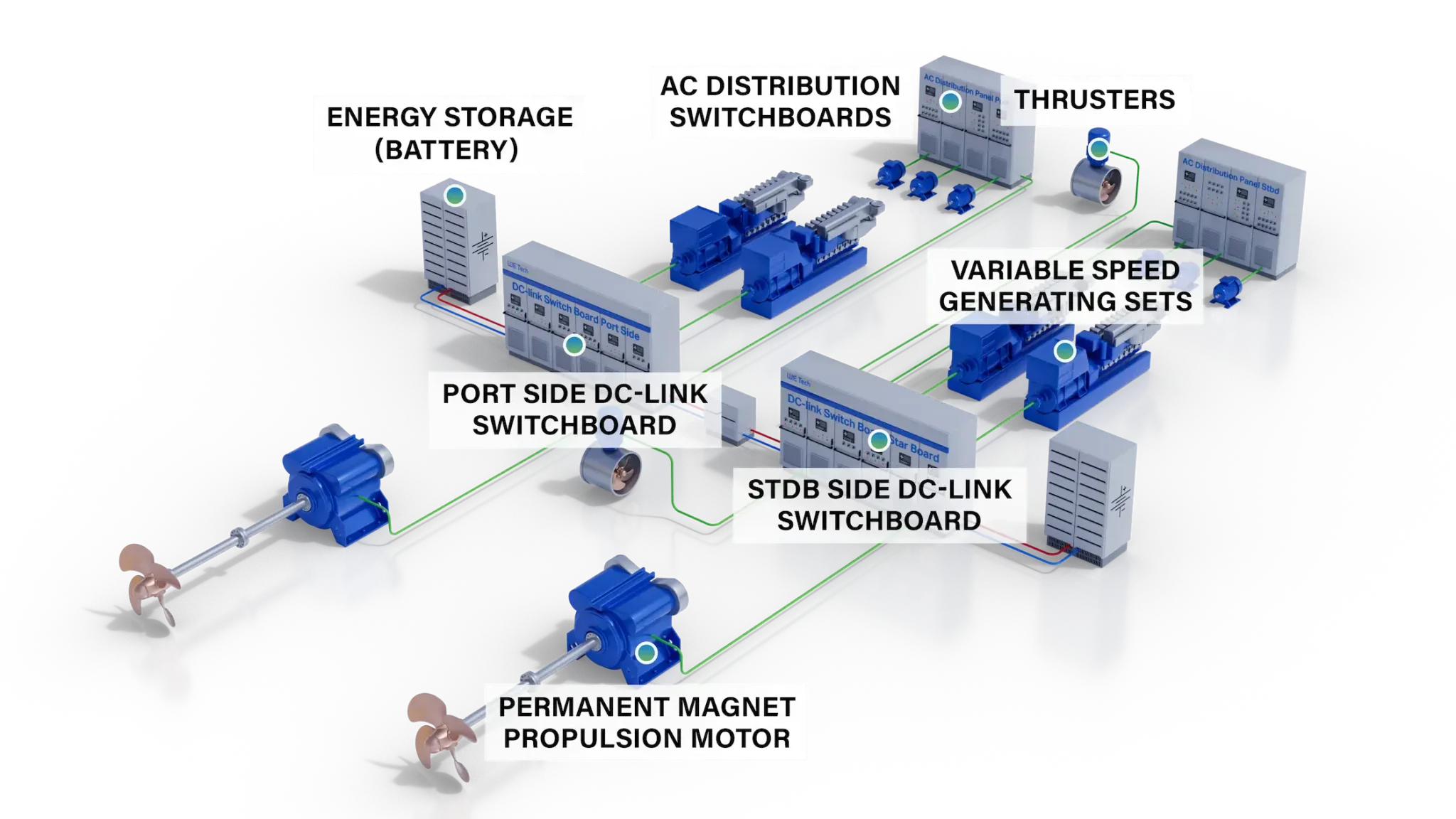

Finally, many shipowners are opting for hybrid systems that combine diesel engines with batteries or, in some cases, fuel cells. Technically, these systems are arranged so that a diesel genset produces electricity for propulsion and onboard services, while a battery energy storage system (BESS) is integrated into the power distribution network. The battery can be charged from the genset when excess capacity is available, or from shore power while in port.

Hybrid battery and diesel electric propulsion system (source: https://wetech.fi/our-solutions/hybrid-electric-propulsion/)

This architecture allows operators to optimize power flows in real time. When demand spikes, such as during maneuvering, acceleration, or heavy hotel loads, the battery discharges to supply the “peak” power. This is known as peak shaving, and it prevents engines from running at inefficient, fluctuating loads. Instead, the diesel gensets can operate closer to their optimal efficiency point, where specific fuel consumption is lowest. At the same time, when demand is low, surplus engine output can be stored in the battery rather than wasted.

The benefits are significant. Studies from classification societies and operators show that hybrid systems can cut fuel consumption by 20–30%, translating directly into lower operating costs and reduced emissions. They also reduce wear and tear on engines by minimizing load cycling, which in turn extends maintenance intervals.

A striking example of a hybrid system is the cruise ship AIDAperla, which was fitted with a 10 MWh battery system in 2020. The installation allows it to operate emission-free while berthed and reduces overall fuel consumption at sea by up to 30%. In Norway, the Color Hybrid ferry uses a 5 MWh battery to sail 12 nautical miles entirely on electricity, cutting emissions in coastal zones. Offshore support vessels in the North Sea are also adopting hybrids to reduce fuel burn during dynamic positioning operations, where batteries smooth out load fluctuations.

In essence, hybrid systems provide shipowners with valuable flexibility. They combine the range and reliability advantages of conventional fuels with many of the efficiency gains and zero-emission capabilities of electric propulsion. This makes them a practical transitional solution, a way to cut fuel use and comply with tightening regulations today, while the industry continues to scale up alternative technologies like advanced batteries, hydrogen, and ammonia. For most operators, hybrid systems are not the final destination but rather a bridge technology, helping fleets reduce emissions in the near term until next-generation zero-carbon solutions become more affordable and widely available.

The Bottom Line.

The shift toward electric marine propulsion is no longer a distant vision, it’s already reshaping ferries, inland barges, and cruise ships. The technology landscape is diverse. Batteries deliver unmatched efficiency and true zero-emission sailing, but their energy density limits them to short- and medium-range routes. Hydrogen fuel cells promise carbon-free operation with longer ranges, yet safety, cost, and infrastructure challenges mean they are not ready to scale across fleets. Hybrid systems offer shipowners a flexible bridge, cutting fuel burn today while buying time for next-generation fuels and storage solutions to mature.

What unites all of these options is the electric drive propulsion system.. Whether powered by a 40 MWh battery, a hydrogen fuel cell, or a diesel-hybrid genset, the motor provides a common platform that can adapt as energy sources evolve. For operators, the question is less about if electric propulsion will play a role, and more about when, and where, it makes the most economic and regulatory sense.

In practice, the industry is converging on a multi-fuel future. Batteries will likely dominate short and medium route shipping, hybrid systems will provide immediate efficiency gains for vessels, and hydrogen or ammonia will likely anchor long-haul decarbonization once the economics and supply chains fall into place. For now, shipowners who move early stand to benefit: lower operating costs, easier compliance with IMO and EU rules, and improved access to green financing. Those who wait risk being locked into aging diesel assets as regulators, financiers, and customers demand cleaner operations.